Rice Husk Briquette Machine and Briquette Plant

Rice husk is a widely used agro waste for processing agro by-products, even though it seems useless. However,

rice husk briquettes are quite useful as a kind of renewable green energy. You can realize biomass briquettes production with Kingman

rice husk briquette machine and briquette plant.

World rice production in 2002/03 was 582million tons. As a consequence, 145 million tons of husk residues were produced. As increasing application of rice husk in rice producing countries, such as Brazil and Argentina, is a fuel in the heat generation for drying rice operations, due to its high calorific power. However, in the combustion process, only the organic part can be burned, giving silica-rich ash as the residue. Rice husk contains a considerable amount of Sio2, compared with other agricultural product. However, because of the biological origin of rice husk, small variations in the silica content can be observed for different rice varieties.

When farmers attain a bumper harvest from paddy fields, generally they care more about production yield of rice, by which they will have ignored the meaningful use of rice husk. Therefore, rice husk is usually cast away as waste after being separated from rice. Otherwise, rice husk from farmers will be purchased or procured by feed or forage plants as one of important ingredients. But many people may have no idea that rice husk can be used to make biomass briquette fuel and rice husk charcoal which as a kind of newly developed green energy will usher in a new round of revolution of energy upgrading from conventional fossil fuel. Biomass briquettes and charcoal have become best-selling green fuel which are also encountering the cold fact that insufficient supply lags behind large demands for briquette and charcoal fuel. Therefore, you will possess quite strong advantages if capable of obtaining ample resources of rice husk.

Get to know other advantages of Rice husk charcoal machine now

Get to know other advantages of Rice husk charcoal machine now

Thanks to the rich content of

crude fibre content, namely, 40% or so of lignocellulose and cellulose and about 20% Five-carbon sugar polymers (also called hemicellulose), rice husk can be made into briquettes and charcoal fuel with high thermal value and cohesiveness. But it, consisting of inner glume and outer glume, possesses the length of 5mm-10mm, 2.5mm-5mm, with the thickness of 25um-30um, featuring golden yellow color, tawny color or brownish red hue. With the bulk density of 96-160kg/m3, rich husk will achieve a higher bulk density of 384kg/m3-40kg/m3 after being crushed. In this respect, Kingman can offer a thoughtful system of rice husk briquette plant with the fitted rice husk briquette press to get rid of compliaction of establishment of a briquetting plant for you. Our briquette plant for sale has been designed with accumulation of experience and practice, and Kingman spares no efforts to be the best briquette press manufacturer and good briquette plant supplier of China for you.

-------------------------------------------------------------------------------------------------

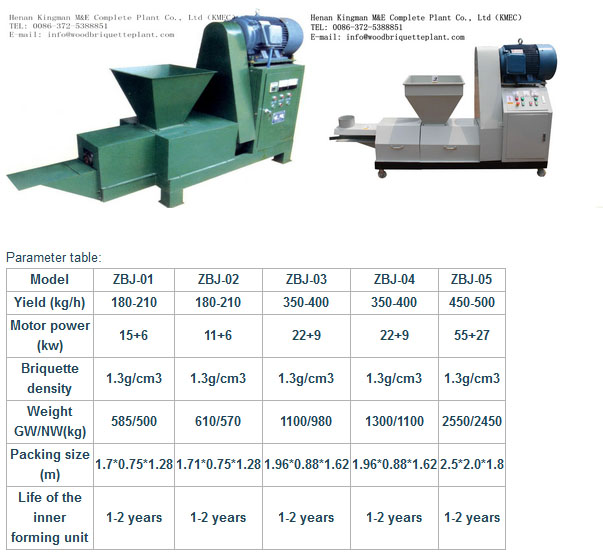

We would like to make a detailed comparison between screw type briquette machine, mechanical stamping briquette machine and hydraulic briquette machine so that you will comprehend the three types of briquette machine well.