- info@woodbriquetteplant.com

+0086 372 5388851

+0086 372 5388851

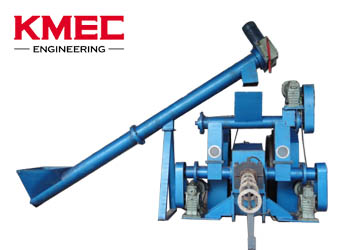

ZBJ-ZT series sawdust briquette machine is one of the most popular products of our company in 2014. It uses automatic temperature control system to adjust the moisture content of raw materials with the features of reliable quality and easy operation. The machine can use sawdust, branches, rice husk, peanut shell, corn stalk, straw, bamboo and other biomass waste to produce charcoal. Circular, square and hexagonal mould can be selected to produce different charcoal, which can be used for boiler heating and or be made into charcoal.

| Model | ZT-01 | ZT-02 |

|---|---|---|

| Output capacity kg/h | 180-210 | 200-250 |

| Motor Power (kw) | 15kw, 380v, six grades | 18.5,380v,six grades |

| Electric heater (kw) | 2.2kw*2 | 2.2kw*2 |

| Heating Range | 280~350℃ | 280~350℃ |

| Life of the inner former | 1-2years | 1-2years |

| Density of briquettes | 1.3 t/m3 | 1.3 t/m3 |

| Weight(kg) | 700 | 800 |

| Overall dimension(mm) | 2700*600*1600 mm | 2000*700*1800 |

| Raw material moisture requirements | 8~10% | 8~10% |

1 Large output: It adopts the improved screw propeller and wear-resistant molding sleeve.

2. Simple operation: The design of automatic control electric heating device can adjust the moisture content of materials stochastically with the features of reliable manufacturing quality, easy to operate, labor saving and power saving.

3 Stable performance: The discharging port is made from the whole cast steel with abrasion resistance and compression resistance, which ensures the material forming stability and improves the working efficiency.

1. The screw can not feed and raw materials turn over.

This situation is caused mostly by the incorrect angle of the screw welding. It can not meet the needs of the specific angle of raw material. Revise the screw angle, wear down the head of screw and increase the screw thrust. The second reason might be that the sawdust isnot dried completely so that the moisture content is higher. They need to be drying again.

2. The density of briquettes can not up to standard and easy to broken.

Occasionally, the briquetting speed is too fast and the briquettes are in low density or even broken into pieces. This kind of phenomenon is mainly caused by the too slanted welding angle of the screw and the head of the screw is too thick. Polish the angle of screw and reduce thickness of the screw head to improve the density. Also, low density of briquettes could also be caused by too high moisture content of sawdust, too large inner sleeve size or the length of screw part is shorter than 365mm.

3. There is transverse, straight or oblique crack in the sawdust briquettes.

There are three main reasons: A, The welding angle of screw is wrong, revise the angle of screw head. B, Excessive wear of internal sleeve hole, repair the internal sleeve or change a new one. C, Wrong composition of raw materials with a large proportion of oil raw material or excessive moisture content so that they need to be dried again.

4. The briquette machine suddenly stopped after producing dozens of briquettes.

This phenomenon is caused by the excessive moisture content of materials or insufficient heating temperature. If the sawdust is not dried completely, then in the hopper of briquette machine, the sawdust moisture in the screw is larger. This is caused by uncomplete drying of raw materials. Users must clean the raw materials in the machine and increase the heating temperature to above 350 degrees, then the briquette machine can start working again.

5. The sawdust briquettes are in pieces and the transverse plane is light and slip.

This phenomenon is caused by the raw materials. The proportion of pine, cypress wood, teak and rubber with high grease in the raw materials is too large. The phenomenon of slipping and not binding can be caused with less than 50% of Chinese fir which contains neutral grease. Adjusting the proportion of raw materials and reduce raw material containing high grease. The grease that sawdust contains is neutral as well.

------------------------------------------------------------------------------------------------------------

Link to other briquette machines hereunder: