Application and development of straw briquette machine

Straw briquette pellet fuel belong to renewable energy, which refer to the dense and uniform briquetting fuel made of straw through collection, dehydration and crushing under certain conditions. After briquetting, the density of raw materials can reach 0.8 ~ 1.3g/cm3, the energy density is equal to that of the medium coal. After briquetting, the combustion performance of fuel is greatly improved, the combustion efficiency is increased from 10%~15% of direct combustion of straw to 30%~40%. The density, strength and combustion performance of biomass are improved instinctively after briquetting, which greatly improves the quality of biomass being used as fuel. Compared with loose straw, the combustion characteristics of straw briquette fuel after briquetting have been improved significantly, and the speed of burning is faster than coal, which not only overcomes the shortcomings of various straw shapes, small accumulation density, not easy to store and transport, but also gains advantages of high volatility, easy to burn, less ash and long combustion time.

Straw briquette machine is widely used for processing corn straw, wheat straw, cotton stalks, rice straw, rice husk, peanut shell, corn cob, branches, leaves, sawdust and other agricultural crops. To strengthen the development and utilization of renewable energy is the only way to deal with the increasingly serious energy and environmental issues and the sustainable development of human society. From the perspective of the production of straw resources, there are a large variety of straws with large production and wide range in villages and towns.

The production of straw are 700 million tons per year in China, although part of straws are used for energy, feed and fertilizer acquisition, there are still 1/3 of straws have not been used, while the majority of which would be desposed in a simple method-burning, therefore a large number of straw resources are wasted. The buring of straw can create no benefit for farmers, it can also causes serious air pollution as well as air, ground transportation problems. Besides, straw burning is also easy to result in fire, threaten people's life and property security and damage to the soil structure, reduce the quality of field, which is not conducive to the sustainable development strategy of rural areas. The main problem at present is that the overall level of straw storage and transportation mechanization is still relatively low and the key technology and equipment are still in the initial stage, which has become a serious restriction to the scale, commercialization and industrialization of crop straw. No matter being used in feed processing, organic fertilizer processing, papermaking, gasification processing or power generation, the first problem to be solved for comprehensive utilization of crop straw is the straw collection. If effective mechanical collection can not be provided, then there is no development to speak of the comprehensive utilization of straw. In views of the relative utilization value and economic value of straw, the development of collecting machinery of low cost is the problem which is urgently resolved in our country.

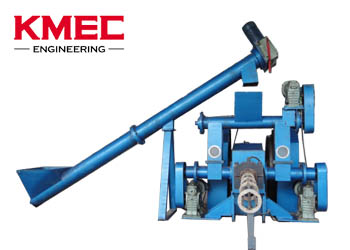

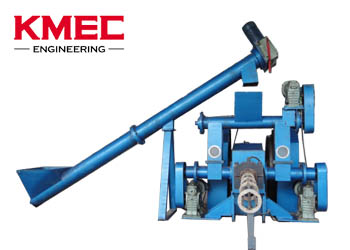

KMEC specializes in the production of

briquette machine, straw molding machine, straw pellet machine and other equipment. Customer's satisfaction is our goal, if you have any questions or requests, please contact us timely.

------------------------------------------------------------------------------------------

Actually the structural design of straw briquetting machine comes from pellet mill. In china, there are three kinds of straw briquetting machine----mechanical press, Hydraulic press and screw press type.