SSJ Series Conveyer

Conveying Equipment

Basic info:

The

belt conveyer provided by

KINGMAN(KMEC) is popular with large production lines (briquette plants taken as example) to transport biomass materials (corn cobs, wood pieces) and usually linked with other equipment such as

crusher or

hammer mill and then transporting smashed powders to

briquette machines and taking final briquettes to storage areas. The maximized density of conveying pile remains around 1.67t/m3. The maximum temperature of conveyed substance shall stay 60℃ or so. The shape and length of the

belt conveyor can be adjusted.

In contrast with the screw type, belt conveyer features a wider range of material conveyance and low maintenance costs.

Parameter Table:

|

Model |

SSJ-I-1 |

SSJ-I-2 |

|

Power (kw) |

1.5 |

3 |

|

Conveying volume (kg/h) |

Adjustable |

Adjustable |

|

Dimension (m) |

4.3×0.56×0.5 |

2.11×0.91×0.7 |

|

Weight (kg) |

130 |

|

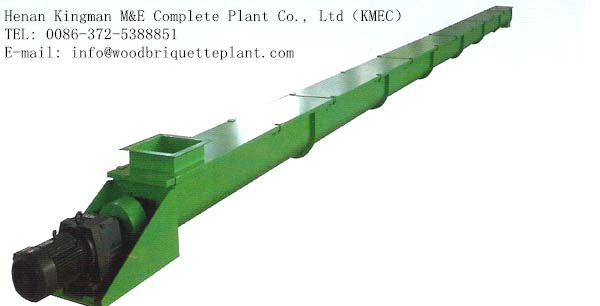

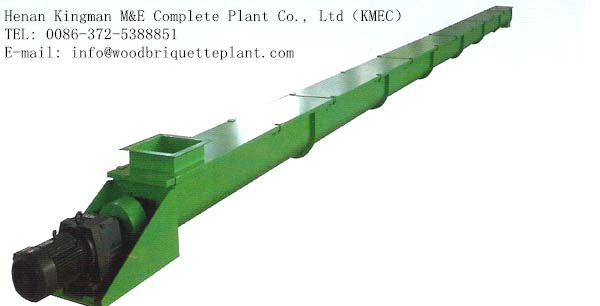

Basic info:

Comparing with the belt one,

screw conveyer is widely put in use transporting powdery material or pisolitic granules. Therefore, both of the

screw conveyer and the belt one can be integrated into a production line organically so that labor quantity can be in this regard reduced.

Parameter Table:

|

Model |

SSJ-II-1 |

SSJ-II-2 |

|

Power (kW) |

1.5 |

3 |

|

Conveying efficiency(kg/h) |

Adjustable |

Adjustable |

|

Size (m) |

4.3×0.56×0.5 |

2.11×0.91×0.7 |

|

Weight (kg) |

130 |

|

Attention: before putting it into practice, ensure the rotating direction of the screw coincide with the conveying direction of a whole line and lubrication shall be carried out in due time.

Iron Net Conveyer

The iron new conveyer is also equipped with motor of 1.5kw and it can be made according to your demands